Insulation Extrusion Line Application for fire resistance cable:

● Electric cable, power cable, energy cable, telephone cable, signal & control cable, fire resistance cable, instrument cable, LAN cable, automobile cable, special cable, etc.

● Thermoplastic compounds: PVC, PE, XLPE, PP, LSHF, TPU, NYLON, halogen-free flame-retardant (HFFR) etc.

● Insulation process type: single layer, single layer + color stripping/ skinning, double layer, triple layer.

Features:

● The extruder can work with TPU, NYLON, LSHF etc. thermoplastic compound by using different design screw.

● With multi-layer extruder, use different crosshead, for single layer, single layer + color stripping/ skinning, double layer, triple layer etc. extrusion.

● Automatic material feed and dryer system.

●With dual payoff or fly payoff and accumulator, non-stop production during change take-up bobbin.

●Crosshead with bypass valve, minimum scrap while quick change color for stripping or skinning.

●PLC control system, line speed, batch production count, cable OD, RPM etc. set and display on touch screen, easy operation.

●“All-in-one” button, cable OD keep stable while speed acceleration or deceleration.

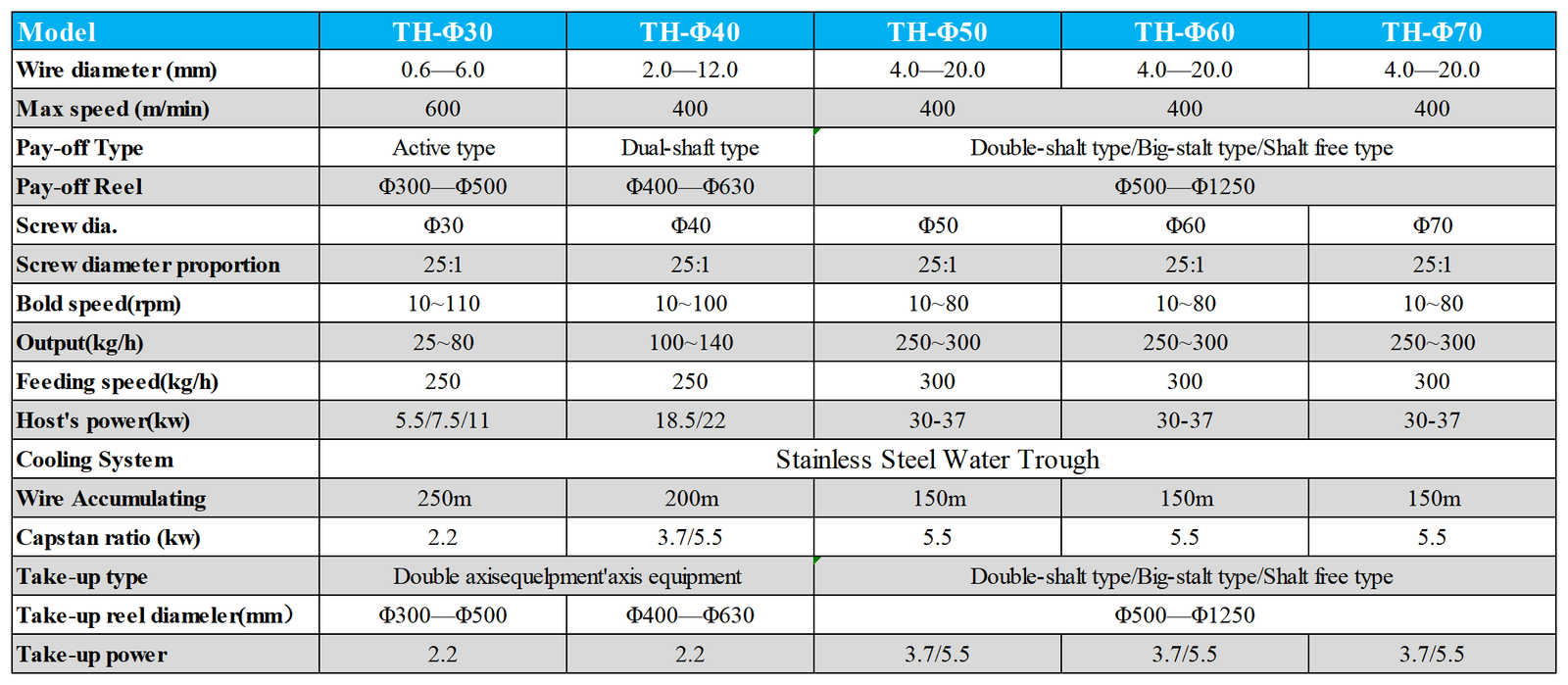

Main technical parameters